About Us

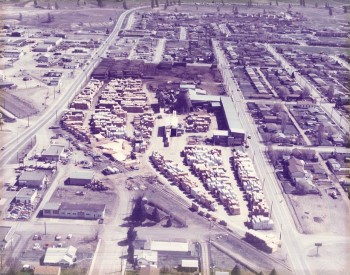

For over fifty years, we have been operating out of Merritt, BC as one of North America’s premier lumber mills. With our combination of high-quality products and a workforce that is committed to helping you succeed, we continue to be the company that is trusted to balance efficiency, safety, and integrity in all areas of our business.

Our History

The Beginning

Arriving from India at the age of seventeen, our founder Tara Singh Ghog settled into life in British Columbia as a welder on the World War Two liberty ships.

At the conclusion of the war, Tara transitioned into sawmilling, where he worked ten-hour sawmill shifts during the day. It was during this time he learned the intricacies of sawing lumber and even acquired his own trucks. In the evenings, he delivered sawdust to the families of Honeymoon Bay, Duncan, Ladysmith and Nanaimo in order for them to heat their homes in the long Canadian winters. In 1947, he entered into a partnership which gave him a minority share in a sawmill. When the sawmill went broke sometime later, Tara had the experience to strive out on his own.

The Move to the Southern Interior and the Beginning of Aspen Planers

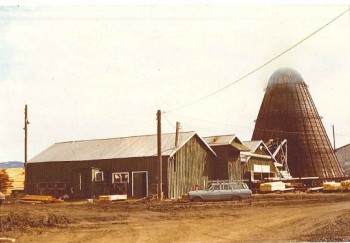

Soon after his first partnership ended, Tara jumped at the opportunity to saw in the Southern Interior of BC. In 1954, he founded Tara Lumber Company, which ran two portable sawmills between Lillooet, Clinton and Ashcroft. In 1959, Tara entered into a partnership to purchase a planer mill and fixed asset sawmill which was then known as Woodford & Sons and today as Aspen Planers (Aspen). Securing the two mills was the start of a new era for the lumber business and a new beginning for the Ghog family.

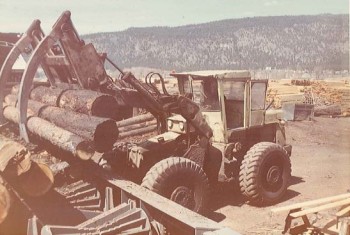

Knowing that the newly acquired sawmill was an antiquated tie mill, Tara decided to rebuild the operation to be an efficient, low cost producer. Following the construction of the new sawmill, there was a period of rapid expansion and growth in the industry and significant consolidation among portable sawmill operators. Tara purchased the first pivot-steered frontend loader in the Nicola Valley, a Euclid L20, nicknamed “The Green Machine”.

Many new government policies were legislated to make better use of the raw fibre supply. In the past, cants were produced in the bush and the resulting slabs were left on the forest floor. Now the cants were primarily hauled to town to be sawed. Government policies stipulated that the slabs must be chipped, and shortly after in 1963, Aspen installed its first chipper.

Tara saved the ensuing business earnings in order to buy out each of his partners and by 1967 the Ghog family had sole ownership of the business.

Sawmill Growth and Development

Aspen kept pace with the growing efficiency of the industry with the addition of a long log bucking station, a new Bradson debarker, double arbor gang and in 1973 a new leading edge Cancar chip n’ saw; which nearly doubled production to an average annual output of 130,000mfbm. At times, the crew could reach up to 170,000mfbm in a single shift.

Towards the mid-80’s, Aspen’s salesman Slim Sidhu had fallen ill and Tara’s sons took over lumber sales. Shortly thereafter was the creation of AP Sales and the new AP branding that is used to this day.

In 1984, work was underway on the next major project in the sawmill; the sorter and new planer design. The design of this new bin system co-ordinated rough sawmill lumber and finished planed lumber to drop into the same bin sorter, which eliminated the old manual pull green chain. When construction began in1985, this project was at the cutting edge of technology and an industry first.

Next Generation of Growth & Acquisitions

In 1988, the business expanded further with the acquisition of the coastal Mill & Timber Products. This was the first step into the cedar business and coastal operations.

Through the early 90’s, upgrades to various equipment and machine centres were performed to further improve mill efficiency. The first LeTourneau log loader was purchased in 1988, which enabled the family to run a single machine in the log yard. In 1994, an optimized board edger was installed, which significantly improved recovery. Rather than chipping the sideboards produced from the headrig, the board edger produced recovery items as a secondary breakdown.

Dating back to 1970, Tara had made many purchases from First Nations for timber on reserve land. In the early 90’s, the ministry of forests presented an opportunity to access small log stands. To manage the small wood license, Surinder Ghog and Chief Gordon Antoine formed a partnership that led to the creation of Qwa’eet Forest Products. Today, the business is owned and operated by Aspen Planers; however, it still operates on the Coldwater Indian Reserve under the name Coldwater Post & Rail and continues to exclusively employ First Nation band members.

In 1999, Aspen acquired Weyerhaeuser’s planing operations in Merritt. Soon after, Aspen was planning its next major step to manage the effects of the mountain pine beetle epidemic on its southern interior fibre supply.

By this time, Tara had passed the business on to his two sons. In 2002, Tara passed away, leaving a legacy of hard work, integrity and commitment to community that defines our operation today. Following the devastating loss of Tara, there was no looking back as the direction had been set and the next major capital project was underway.

In 2003, the installation of the DDM allowed Aspen to utilize the dead pine logs that were left in the aftermath of the mountain pine beetle, while increasing manufacturing capacity to over 350,000mfbm annually. In 2006, Aspen rebuilt the planer mill on the recently acquired Site 2, which included a Comact grade expert that more accurately grades lumber.

Although the subprime mortgage crisis of 2007 made for tough times in the business and the industry as a whole, the mill continued to demonstrate its core values of hard work and thriftiness to position itself for a market recovery.

On to a Brighter Future

Emerging from the recession, Aspen began to acquire various timber allocations to bolster its position in the Nicola Valley. The next major acquisition was in 2009, with the purchase of Ainsworth’s peeling and plywood operations in Lillooet and Savona. The additions to the Aspen family have not only increased our manufacturing capacity and diversified our product range, but also revitalized the communities in which they operate.

Today, Aspen continues to be an independent family-owned business in the wood products industry and is carefully charting its course into the future.